The thermocouple device is the most widely used component to monitor the burner flame and to guarantee safety by detecting the presence or absence of flame. The thermocouples are used for both gas ovens and gas burners with pilot flame, or any kind of gas hobs. They are supplied with various lengths and different type of fittings.

We design and manufacture a wide range of highly reliable thermocouples for domestic and industrial applications which can be used with any type of gas. Depending on the customer requirements, the opening time in the ignition phase and their closing time in the shut-off timing of magnet units can be adjusted with proper use of thermoelement material and size. It is also possible to make thermocouple ranges from 15cm to 180cm.

Pars Flame Controls supplies range of thermocouples to the market which are able to equip different types of burner and to combine with different types of magnet. With customer requirement, it is possible to offer switch on time in 1 second as well as switch off time between 15 to 30 seconds thermocouples, in order to satisfy customer needs.

A thermocouple should satisfy customer needs by providing following product characteristics:

Single wire: an advantage of this type is there is no need to ground wire. Also, conductivity is carried out using the metal surface of the hob. The guarantee of a suitable contact between body and hob is obtained with thread and nut block to the burner or the cooking hob itself. Fastening with a clip is not recommended.

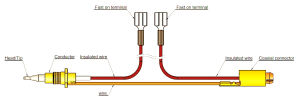

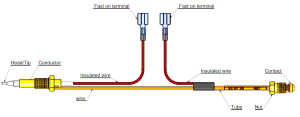

Fast-on connection: this is suitable for valves with fast-on connection. This model is equipped with a ground model wire thus allowing for an easy and safe fastening of the burner body with a clip. The ground wire can be fixed with a screw in a single point, preferably close to the tap.

Pars Flame Controls is able to offer oven thermocouples for applications with thermostats, oven double wire with fast connections. Hence, the body of fastening the thermocouple can be customized based on the type of burner and fast coupling connections of fast-on for different types of gas valves.

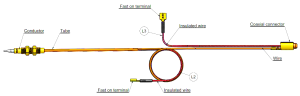

The tubular thermocouple can be used for both gas ovens and gas burners with a pilot flame, or in ovens in which a connection thread to the thermostat is forecasted.

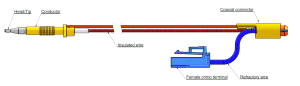

The double wire thermocouple is indicated for gas ovens. The copper tubular part remains inside the cavity, guaranteeing mechanical and thermic protection to the phase wire and protecting it in its passage through the metal plate. Compared to the tubular models it has the advantage of cabling flexibility, favoring the speed of assembly.

|

Fixing connector torque: ~3Nm Minimum bending radius: ≥ 15mm A= Ignition Time B= Shutdown Time |

Ignition Time: ≤6 seconds Shut down time: 30-60 seconds F.E.M. at 100°C: ≥ 2mV Resistance: =9 + (0.015 * L ) ± 4 m Ω Maximum tip temperature: 800°C |

To define product range the following factors are considered from each customer: